How does JH PCBA control your

PCBA boards quality?

Learn More

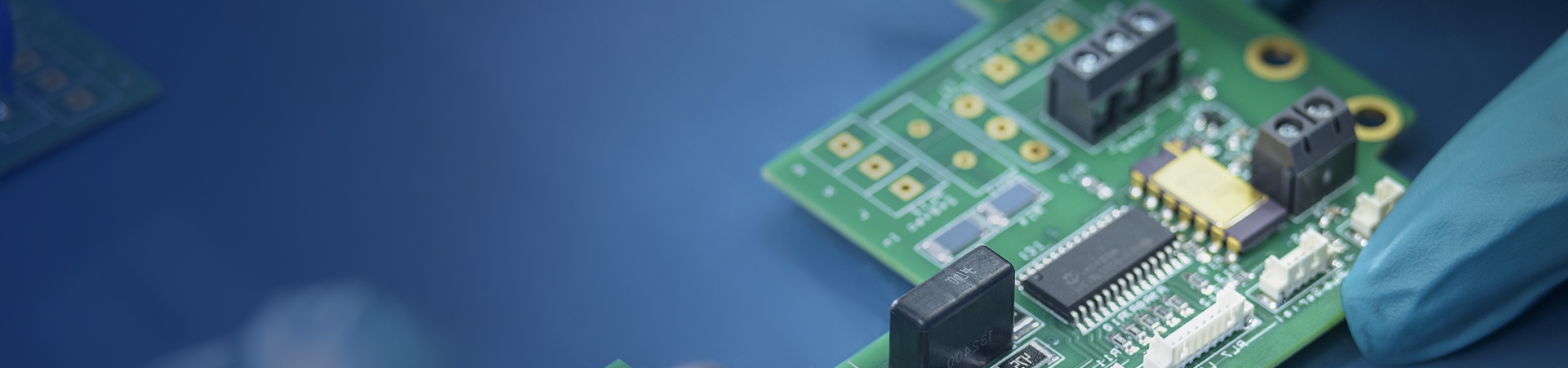

JH PCBA , equipped with advanced production and inspection equipment, automatic components storage and production management, strict quality control, professional operators and intelligent service system to ensure the standardization and best quality of each production process.

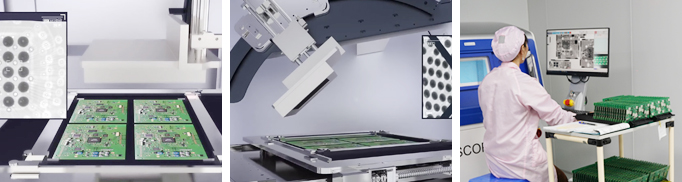

Advanced Production and Testing Equipment

Barcodes vs Qr Codes for Inventory Management

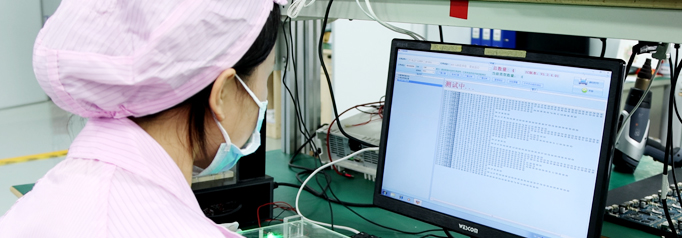

MES System, real-time and visualization production progress

MES System, real-time and visualization production progress

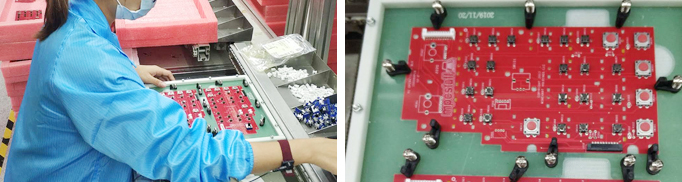

Production site 5S management

·Clean, dust-free workshops, anti-static 5S system management

·Standard SOP for operation, implement more strict IPC-A-610-G standard than others

·MES System, real-time and visualization production progress, can reduce labor and depreciation rate

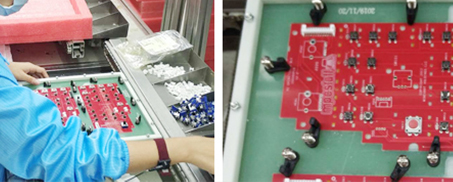

Production Automatic Management

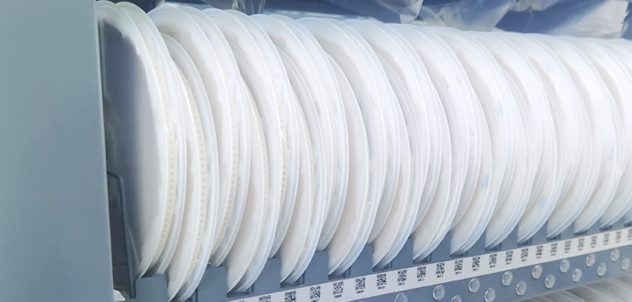

Wrong material prevention system on SMT Pick&Place Machines

QR code double check before load on SMT machines

Components Storage Automatic Control

PCBA Quality Control Key Process

Solderpaste

·We choose famous solderpaste brand like Senju, Alpha, Kelitai, Chuanze, etc.

·We apply automatic solder paste mixing machine to stir clockwise for 2-5 minutes until the solder paste reaches a filamentous state and immediately use for production.

·We only use famous brand laser stencil and pay highly attention to the high precision solderpads like QFN,BGA ect.

·Our 3D SPI controlling the solderpaste thickness,area, volume distribution with the non-contact laser 3D scanning intensive sampling technology.Workers can easily find out the solderpaste issue in this step to avoid soldering issues before the PCBA go into oven.

PCB SMT Soldering

④ We have X-ray equipment to check the soldering quality for BGA chips.

⑤ The first article inspection is required before we can run the rest production. For example, the design information and designators and components value will be imported as a database to verify if the first article fully match the specifications of client’s design files.

① We have 4 automatic Pick&Place production lines, equipped with YAMAHA brand YSM10+YSM20R, electric feeders, perfectly achieve 0201, 01005 SMT precision, support common IC, BGA, QFN, PLCC and other components of precision package components assembly. Wrong material prevention system prevents workers from loading wrong components and causing quality accidents.

② Our reflow oven has 10 temperature zones, which will leave more time for solder paste mealting and solidification, make sure the temperature rising and dropping more steadily,this will help to prevent a lot of soldering quality problem caused by the thermal shock.

③ AOI equipment is used in the end of our every production lines. AOI machine automatically scans PCB through the camera and collects images to compare the actual solder joints with the qualified images in the database.This will easily find out the soldering issues and improve a lot our QC’s efficiency.

④ We have X-ray equipment to check the soldering quality for BGA chips.

⑤ The first article inspection is required before we can run the rest production. For example, the design information and designators and components value will be imported as a database to verify if the first article fully match the specifications of client’s design files.

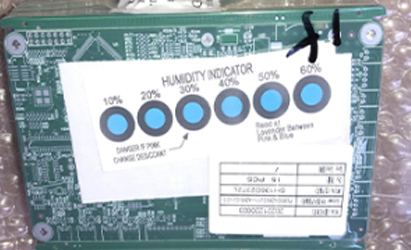

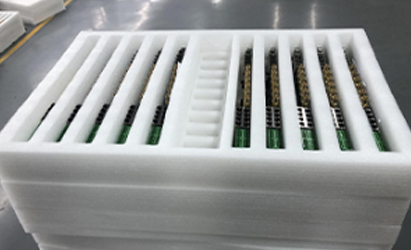

Package

PCBA board is a fragile and easily damaged product. We always carefully packed with bubble bags, pearl cotton, electrostatic bags

before transportation to prevent the damage causes by static and crushing.

Quality Certifications

By continuously upgrade manufacturing technology, optimize management standards, JH PCBA has passed several

international quality and environmental certifications, ISO9001: 2015, IATF16949: 2016, Rohs, SGS, we are confident to provide

professional turnkey PCB service to our worldwide customers.

ISO9001 Quality System Certification

IATF16949:2016 Automotive Quality Management System Standard certification

IPC610 CLASS III PRODUCTION SPECIFICATION

≤0.2%

Quality complaint rate ≤ 0.2%

Resolving Quality Issues

By continuously upgrade manufacturing technology, optimize management standards, JH PCBA has passed several international quality and

environmental certifications, ISO9001: 2015, IATF16949: 2016, Rohs, SGS, we are confident to provide professional turnkey PCB service to our

worldwide customers.

Unacceptable processing defects

Fail to meet tolerance requirement

Incorrect material / finish

The part is not machinable

Product not available

Other reasons

Recognition & Awards

The quality and service of PCBWay have been trusted by many customers, platforms and wel-known bloggers. and have reached a long-term

cooperative relationship with them. Discover our customers' testimonials.

PCBWay and Samsung have collaborated for several years in the design and manufacturing of PCB(s). PCBWay's expertise in technology development and manufacturing complementsSamsung's 20-year experience in the development, sales, marketing and Cusomer Service in PCBproects, continuously strengthening their leading position in the international markets.

PCBWay and Samsung have collaborated for several years in the design and manufacturing of PCB(s). PCBWay's expertise in technology development and manufacturing complementsSamsung's 20-year experience in the development, sales, marketing and Cusomer Service in PCBproects, continuously strengthening their leading position in the international markets.

PCBWay and Samsung have collaborated for several years in the design and manufacturing of PCB(s). PCBWay's expertise in technology development and manufacturing complementsSamsung's 20-year experience in the development, sales, marketing and Cusomer Service in PCBproects, continuously strengthening their leading position in the international markets.