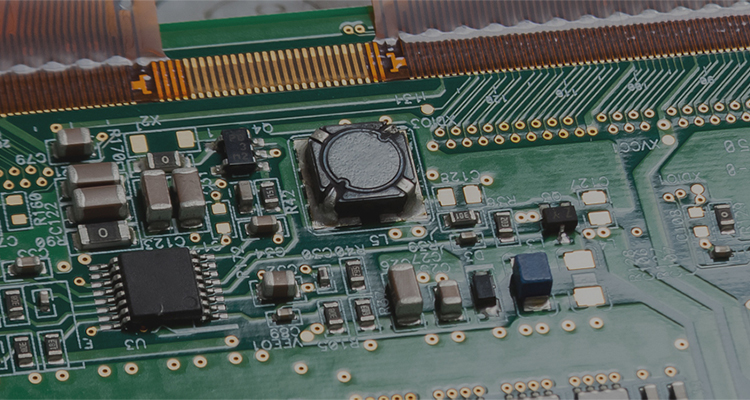

JH PCBA Service Overview

We offe Kitted and Full Turnkey Assembly service. Whether you supply the parts or we do, our certified assembly technicians can build your quality products with

state-of-the-art SMT and Through Hole Equipment.

Surface Mounting(SMT)

Through Hole(THT)

Mixed Technology(SMT+THT)

Single or Double-sided Placement

Hand Soldering

Box Building/Finished Products Assembly

Passive Down to 01005 size

Ball Grid Array(BGA )

Quad Flat Package No-lead(QFN)

Quad Flat Package (QFP)

Small Chip Package(Pitch of 0.3mm)

Type of Services

Our state-of-the-art facility uses the latest SMT and THT equipment to manufacture

quality and reliable products in a timely fashion for our customers.

| SMT Production Lines | Hand Soldering Lines |

| THT Production Lines | Functional Test Lines |

| Automatic Loaders | Conformal Coating Spraying Machine |

| GKG(GSE) Solder Paste Printer | X-RAY BGA Inspection Machine |

| GKG(G9+) Solder Paste Printer | AOI ALD7120 |

| SINIC-TEK S8030 SPI | AOI VCTA-A410 |

| YAMAHA High-speed Pick&Place Machine | Smart SMT First Article Inspection Machine |

| YAMAHA YSM20R | Microscopes (with measurement function) |

| YAMAHA YSM10 | Automatic PCB Splitting Machine |

| Jintuo JTR1000 10 Zone Reflow Oven | Washing Machine |

| Nitto Wave Soldering Machine | Forming Machine |

| Item Name | PCBA Description&Capability | |

|---|---|---|

| We offer |

① Senie Fectoc esim PCR Desm 2 PCB ad mauctun Cmns r PaS SUC PCBASVT-Thu-d Fucona es. Wre soen. ox udinoFiristhed Podussembly etc one stop PCB solutions ② Volume: prototype. expedite prototype, small&medium amount, big amount pcb & pcba manufacturing service ③ Components Scourcing: Kitted, Partially Kitted, Turn-key |

|

| Files leedec | General | Gerber Files+BOM File+Centroid File ( other names maybe:aka insertion, Pick-N-Place, or XY Data) |

| Gerber file | Gerber Files+BOM File+Centroid File ( other names maybe:aka insertion, Pick-N-Place, or XY Data) | |

| BOM File |

BOM file should clearly and full description of every kind of component, need at least below items wanufacturer Part Numbe Manufacturer or Brand Specific description of components parameters and specification, including such as voltage, resistance, capacitance etc ocation Number according to PCB silkscreen file Quantity |

|

| Centroid File | Describe the location and distance of every component | |

| Kitted Service |

Ated: Customer provide the PCes al he parts ad al the reouired fles, in this cas. dease send us al the comonens wih BoM fe and delaied dakin ist indicaio tem rumber, customer or manufacturer's part number and quantity in kit. BOM file in this case should including: line# Quantity Per Part Number Reference Designator Manufacturer Part Number Part Description |

|